Starting a business is not an easy endeavor. There are many things that must be considered before doing so. Ensuring quality products, sourcing of materials, logistics, strategies and more.

The good news is that there are a variety of readily available resources that can teach anyone how to start and run a business. The not so good news? Despite all the available resources, there are still a number of things that people overlook.

One of these things is transportation. Transportation plays an important role in most – if not all – businesses. You’ll need it to ship materials and even the product when it is ready. Getting the raw materials and the products to the right place at the right time will do wonders for a business.

Transportation also speaks about your operations within the plant. Perhaps it could be through the various phases of the product development process. It may move from area to area, or team to team.

In a previous article, we spoke about the Lean Logistic Principles. It is a philosophy that focuses on eliminating waste and maximizing the value of a company. This is why it is called “Lean”.

Now though, we’ll look at other facets of a business, specifically transportation, and see how the lean principles can be applied to it. Let’s learn more about Lean Transportation.

Applying Lean Principles to Transportation

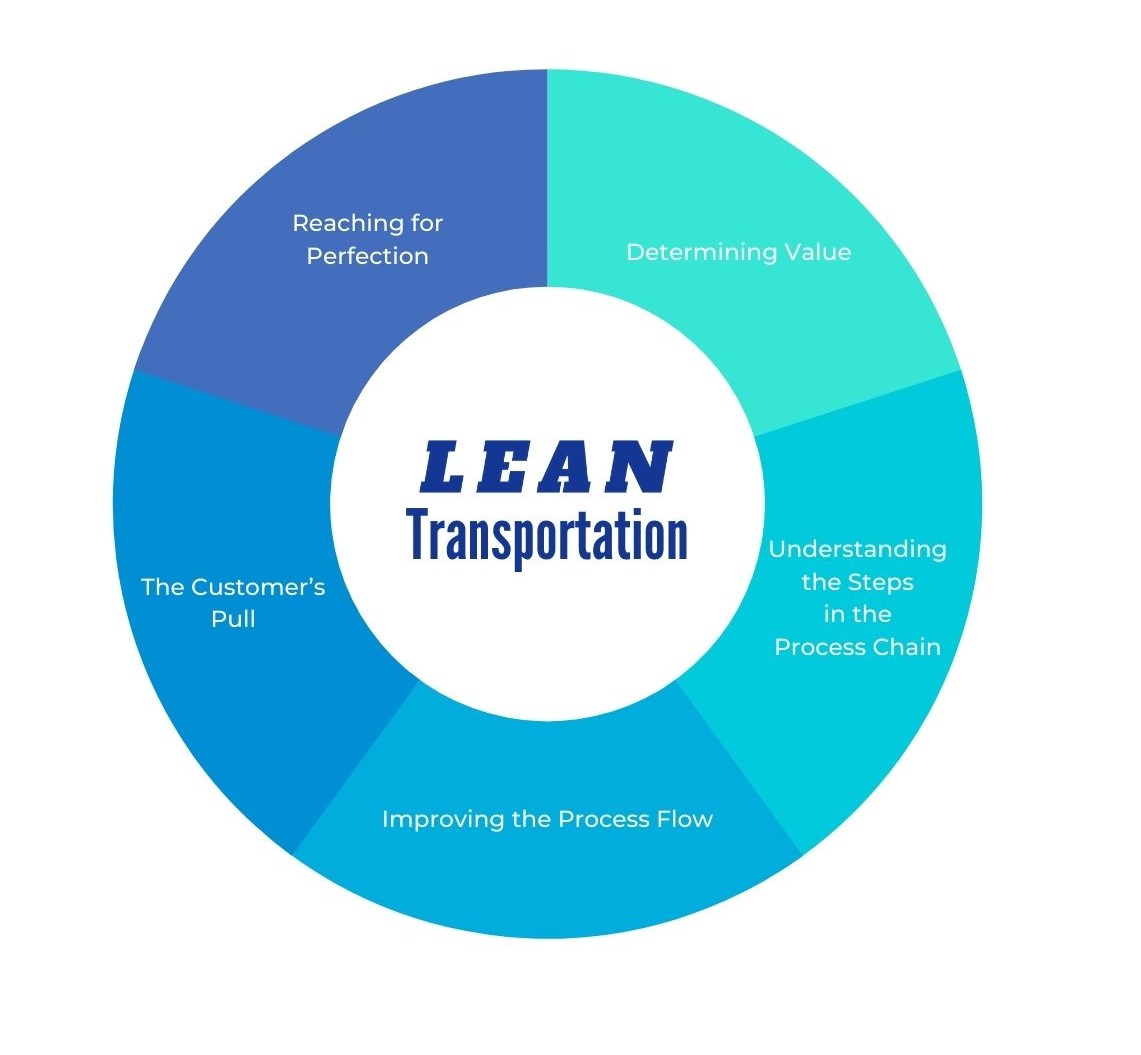

There are 5 lean logistic principles in all. These are:

- Determining Value

- Understanding the Steps in the Process Chain

- Improving the Process Flow

- The Customer’s Pull

- And Reaching for Perfection

Several of these principles can be directly applied to transportation. Here’s why.

Determining Value and the Customer’s Pull

Value is one of the most important things in a business. Understanding the value of a business will allow you to focus your energies and efforts on it. This results in less spending and more earning.

Like in business, the value in transportation lies with the customers. It must be understood how the customers’ experience with transportation is like.

Develop a transportation strategy that will meet and even surpass customer needs. It should be tailor fit to their needs.

Understanding the Steps

As said previously, the Lean philosophy is all about eliminating waste and maximizing value. Waste is anything that does not directly contribute to value for the customer and the company.

In order to see the wasteful practices in your organization’s transportation system, you must first understand the steps within. Whether it be transportation delivery for raw materials or getting your product to the customers, you must understand each and every step that takes place.

While transportation is vital, if you are transporting with excess, it does not work in your favor. This speaks to creating more inventory than the customer is willing to buy. In the same way, the transportation of these products within your facility is a waste unto itself.

Improving the Process Flow

After the waste has been eliminated, it is now the opportunity to improve the flow of the business’ transportation and set in motion an effective strategy.

One action that can be added to the process flow is by performing a daily event management.

Start off each day with a transportation plan and have the day run as per usual. It is very important to have visibility of the actions that happen within each hour. Once the day is done, this data will allow you to look at the plan of the day and see how it can be further improved.

Reaching for Perfection

Perfection is never achieved, but the action of aiming for perfection does wonders. The process flow should be continuously monitored and improved upon. Continue identifying and eliminating waste, and your transportation system will benefit from it.

Wastes in Lean Transportation

With regards to transportation, there are many things that can be considered waste. As stated previously, the first one is an excess of inventory.

If a facility is overproducing inventory, this means that customers are not willing to buy all the products that the business is creating.

Apart from that, it also means that within the process flow, there are certain items that take up time and effort but do not create any value. The business would be better off producing the exact number of products rather than overproducing.

One other waste in lean transportation is the layout of the facility. Oftentimes, products are transported between certain functions. These widely vary depending on the product being created.

This relates closely with the understanding of the process flow. If your product goes from welding to pressing, but the two stations are so far apart, then this creates a waste of time. This can be remedied by looking at the layout and placing related stations next to each other.

Benefits and Challenges of Lean Transportation

Up to now, we’ve been speaking about specifics of lean transportation. However, what are the actual benefits of applying to lean to your transportation system?

- Reduced costs – The first is reduced costs. In truth, this benefit is at the core of the lean principles. Taking out waste will instantaneously ensure that you are spending less. This can be in the form of procuring less supplies or shipping less frequently.

- Increased employee production – When a process is made lean, this will remove certain roadblocks and steps that hinder the employee from producing more. A lean process means that employee efficiency is at an all time high. More things can get done faster this way.

- Increasing profit – Closely related to the previous two benefits is the increase in profit. Spending less while producing more efficiently means that you stand to rake in more profit.

At the same time, there are also many challenges for lean transportation.

- Increased Costs – This seems counterintuitive to the benefit above. However, as the saying goes, you have to spend money to make money. There may be times where you will need to purchase new equipment to ensure smooth and efficient production.

- Temporary Increase Labor Costs – This challenge relates to the second benefit above as well. There needs to be considerable effort put into creating the improvements needed in the production area. While improvements are being implemented, labor costs will temporarily increase.

- Fear of Change – The final challenge is with the perception of people. While change is a constant, human nature sometimes dictates that some people will be afraid of change. This may cause some opposition to your proposed improvements.

Lean Transportation Transforms Businesses

All in all, applying lean principles to your businesses’ transportation systems has the ability to transform it for the better.

The improvement may take a while to show itself, but these tried and tested principles will surely cause an increase of profits.

Try out lean transportation today and see all the good it will do for your business. `

You might also wanna check Top Lean Logistics Principles.