Blog

JIT Implementation: Key Challenges and Solutions for Success

Just-in-time (JIT) methodology focuses on producing and delivering products precisely when needed, without waste or delay. JIT has become increasingly popular in supply chain management due to its ability to reduce costs, improve efficiency, and increase customer satisfaction. However, implementing JIT does not come without its own set of challenges. This article will explore the key challenges of JIT implementation ... Read More

Read More5S Methodology: The Ultimate Guide to Workplace Organization

The 5S methodology is an organization system for workplaces used in manufacturing and other industries for decades to improve efficiency, reduce waste, and increase safety. It is also considered one foundational pillar of having a Lean company. The 5S’s stand for the procedures that include Sort, Set in Order, Shine, Standardize, and Sustain, and each S represents a different step ... Read More

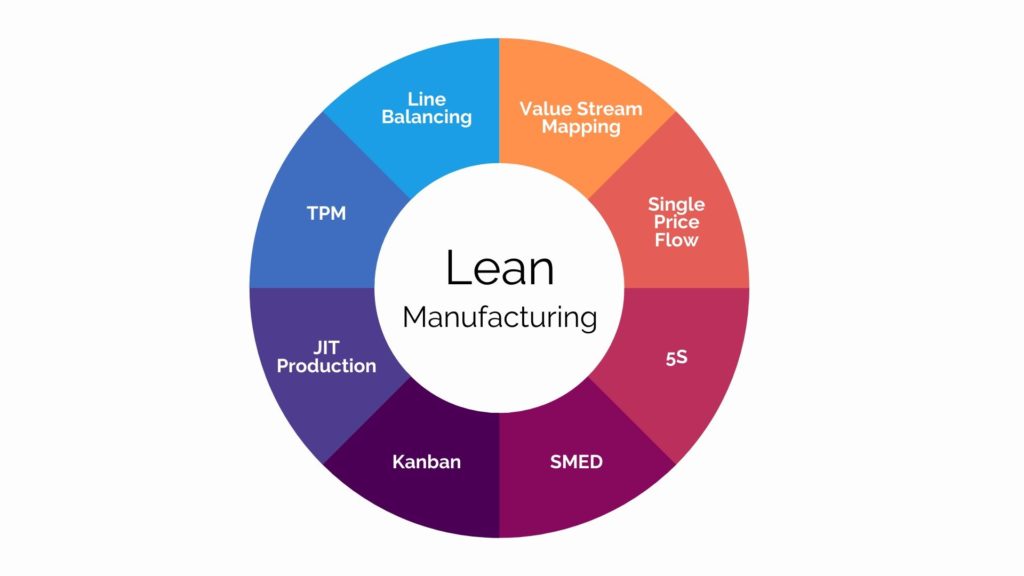

Read MoreA Complete Guide to Lean Manufacturing – Lean Factories

Lean Manufacturing is a way of thinking that can be applied in any industry, but is most commonly used in the manufacturing and production industries. It is a strategic and operational method that seeks to eliminate waste and improve quality and efficiency. By understanding what Lean Manufacturing is, you can begin to incorporate its principles into your own business or ... Read More

Read MoreLean Project Management Tools: What You Need to Know

A project manager's life is a constant juggling act. You have to ensure that all your tasks are on time and within budget, while also keeping the team motivated and happy. The last thing you need is more work! Fortunately, there are plenty of tools out there to help you manage your projects more efficiently, but which ones should you ... Read More

Read MoreTop Reasons Why Lean Is Not Only For Manufacturers

When people think of Lean, their minds often wander to manufacturing. While Lean was originally developed to benefit the manufacturing industry, the fact that it has been practiced effectively has raised the eyebrows of many other industries. These industries now seek to employ the effective practices of lean and recreate the same success that it has created in manufacturing. Let’s ... Read More

Read MoreHow to Know if Your Facility is Truly Lean

Now apart from approaching and ensuring success, the Lean methodology has a slew of other benefits as well. For starters, the wasteful actions that Lean takes care of will allow for a more focused workforce. This isn’t just a focus on their tasks, but on things that contribute great benefit to a facility’s success.

Read MoreTop Benefits That Lean Manufacturing Can Provide Businesses

Efficiency will always be a big benefit to each and every business. The act of producing more with less will save on time, efforts, and resources, while also increasing the profit and success of a company. That is why Lean Principles is particularly useful, especially to the manufacturing industry.

Read MoreHow to Apply Lean Manufacturing Principles to Engineering

Studies have shown that 80% of a product’s cost is determined when the design of the product is being engineered. The factors that contribute to the product’s cost at this phase include:

Read MoreEstablishing Lean Factory That Works: Top Tips to Consider

Lean is a philosophy and system that can be applied to a variety of workplaces or processes. The main goal of lean is to do away with any waste wherever they can be found within your business. Fortunately, the lean system and all of their benefits can be applied to factories. The question now is, how does a business establish a lean factory that works? Let’s go over several top tips that businesses consider when applying lean to factories.

Read MoreHow Can Lean Logistics Benefit Your Business

People think that terms like, “Lean”, “Lean Manufacturing”, and “Lean Logistics” all mean the same thing. While they pull from the same philosophy from Japan years ago, there are some differences to them. When people just say Lean, it refers to a general plan of attack that can be applied to any process or any business with the goal of eliminating waste. When the term “Logistics” is added, it adds a whole new complexity to how the Lean methodology is used. It then focuses the Lean principles to a different more complex set of operations.

Read MoreImportant Single-Minute Exchange of Dies (SMED) Techniques Used in Manufacturing

LEAN’s main goal is to minimize waste and maximize productivity. We have covered many different techniques that can help do this. These include Shingo, TPM, and even the Six Big Losses. One of the pillars of LEAN is addressing the swift changeover of equipment. If the changeover time is quick, this means that downtime decreases drastically for improved efficiency. This is important, as downtime is a big waste that must be minimized or done away with. Thus, we go to Single-Minute Exchange of Dies or SMED.

Read MoreKanban: A Means to Achieve Just-In-Time Manufacturing

Kanban is a visual workflow management system for any work that follows a process. It imagines the whole workflow process, as well as the actual work as it goes through each step of the process. The objective of the Kanban method is to eliminate any roadblocks that may hinder all the other steps from taking place and any work being finished.

Read MoreSix Big Losses: Important Concepts to Always Bear in Mind

Many other methodologies we have discussed look at productivity loss through the lens of a variety of factors. These include things like the process flow, people, and other factors that organizations can eliminate waste from. The Six Big Losses is similar in that account. It was created to identify and categorize how a business encounters productivity loss from the perspective of the equipment that the company uses. It works hand in hand with OEE, as it provides more detail on equipment loss.

Read MoreEverything That You Need to Know About Lean Transportation

One of these things is transportation. Transportation plays an important role in most - if not all - businesses. You’ll need it to ship materials and even the product when it is ready. Getting the raw materials and the products to the right place at the right time will do wonders for a business.

Read MoreCycle Time Versus Throughput in a Manufacturing Process

Throughout our articles, we have been talking about multiple techniques and strategies for lean practices in manufacturing. The question for this article is, how does one measure the performance? This is where cycle time and throughput come into play. These closely related measures are very closely related to each other, but have some distinct differences. Understanding both concepts will allow you to improve performances, from managers all the way to supervisors.

Read MoreTop Lean Logistics Principles

All businesses and business owners desire one thing: success. For many, this is by increasing revenue. Different people have different ideas on how to do this. However, one often overlooked thing is by eliminating waste. With less waste, products and services can be delivered faster and more efficiently.

Read MoreTop 5 Essential Lean Manufacturing Tools

Most manufacturing companies around the globe are now going the Lean Manufacturing way. Lean manufacturing is more than just a method. It is an all-encompassing business strategy where waste or anything in the manufacturing system or process that does not add value, is reduced, without compromising productivity and quality. To carry this out, companies must determine the right Lean Manufacturing tools to use.

Read MoreWhat is JIT (Just in Time) Manufacturing (Why You Need It)

Inventory management is a crucial part in any business in that it can make or break its overall condition. Stocking up on your products can allow you to meet the demands of your customers anytime they need them. But it will also require a bigger storage space and will run the risk of ...

Read MoreLean Manufacturing Training Materials

Using Lean principles in manufacturing is a great way to improve the quality of a product and service. Moreover, if used correctly, it will definitely improve a company’s financial performance overall. If you are in the manufacturing industry, manage a manufacturing industry, teach employees ...

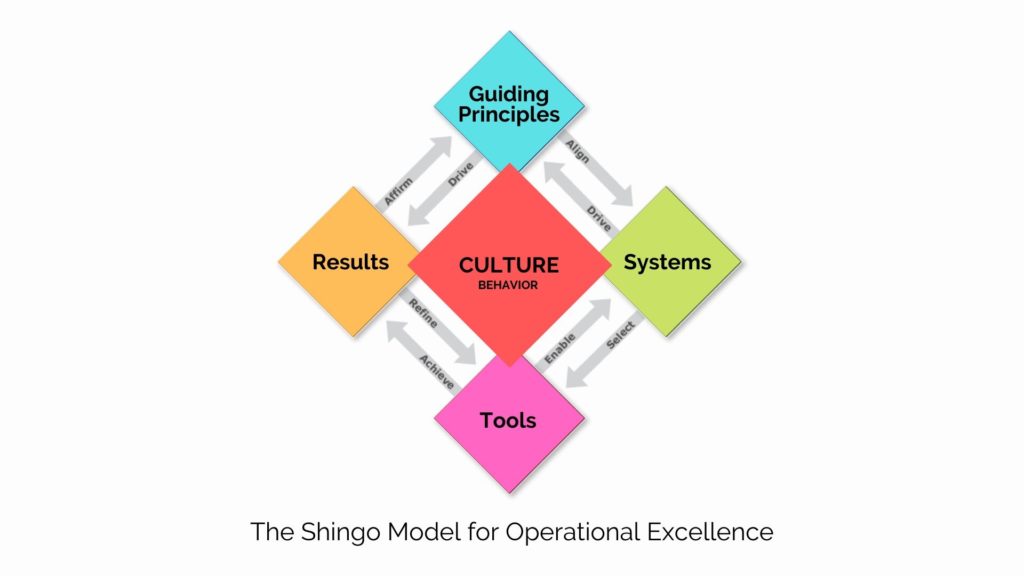

Read MoreShingo Guiding Principles

For people who are handling businesses and processes, there is a misplaced focus on tools. The belief is that the right tool will solve most, if not all problems. However, another belief states that the tools are not the endgame. They aren’t even the starting point. Enter the Shingo Guiding ...

Read MoreThe Reshoring Initiative

The pandemic has hit all countries from around the globe. Not only has the pandemic affected people’s lives and health, but it has also affected the economies of various countries. The delicate balance and business framework that has been steadily built has been smashed, like a boat ...

Read MoreTPM and Six Sigma Basics

Six Sigma is usually termed for a process that is well-controlled. It is a methodology that has set tools and processes. These tools and processes are used to improve the overall performance of an organization or business. The increase in the business’ performance coupled with the ...

Read MoreGemba Boards

Running a business or managing a team is a challenging endeavor. Fortunately, there are a great number of tools that people can use to understand the various problems and statuses within the workplace. One tool that can be used is the Gemba Board. The Gemba Board is taken from ...

Read MorePoka Yoke in the Kitchen

We have looked at common poka yoke examples in daily life. But I thought it would be a nice thing to zero down on other poka yoke examples in specific areas. These new series of posts will start with poka yoke examples in the kitchen. From the basic equipment to cooking methods, you will find that the kitchen is full ... Read More

Read More3 Reasons Why Jidoka is not an Important Lean Tool Anymore

Jidoka Basically, Jidoka is a Japanese word that means giving machines human intelligence — this helps in building in quality into products. Stopping to fix problems is and developing countermeasures ultimately leads to better productivity in the long run. But Jidoka is not only about machines that can stop themselves. In line with the TPS philosophy, Jidoka is also about ... Read More

Read MoreKaizen Musings — Defective Provision Processes

Companies fail at lean provision because they still use mass production methods. Satisfying customer demand may look easy -- especially with today's technological advancements. The truth is that providing what the customer wants is not easy. This is because the whole process is ...

Read MoreKaizen Musings — Lean Inventory Management

Summary Inventory quantity is a measure of how well lean has matured Reducing inventory without streamlining processes can be a recipe for disaster Inventory velocity is more important than inventory reduction Supplier management to align to lean goals is key How inventory is received matters Inventory is Muda The ideal situation in lean is to have zero inventory. But for ... Read More

Read MoreKaizen Musings — In Lean, Slow is Better than Fast

One of the greatest selling points of lean is that it leads to faster throughput. You would expect people in a lean plant running around frantically producing goods very fast. But the reality in a truly lean organization is markedly different. While the output is very high, you will also notice that people are working at a comfortable pace. Why ... Read More

Read MoreLean Healthcare : Implementing a Hospital Lean Management System

Lean is slowly catching on in healthcare because of the immense benefits that could be gained in quality, cost and delivery.

Read MoreKaizen Musings — Why Is There So Much Stress At Work

Why is there so much stress at work? Work related stress can be overcome through simple habits.

Read MoreBenefits of Total Productive Maintenance

Benefits of Implementing Total Productive Maintenance Why do we practice Total Productive Maintenance? The simple answer is that we want our critical machines to be in a good working condition at all times. When this happens, we are able to satisfy customer demand. Total Productive Maintenance improves flow within the value chain through elimination of downtime caused by machine breakdowns. ... Read More

Read MoreNemawashi Model for Decision Making

Nemawashi is consensus based | Source What is Nemawashi? Nemawashi is a Japanese term which literally translated means ‘work around the roots’. It is a consensus building technique that aims at removing obstacles to proposal approval by seeking an informal audience with the decision makers before a formal meeting is held. The concept is not about lobbying as many people think of ... Read More

Read MoreHOSHIN KANRI — Policy Deployment Meaning & Examples in Manufacturing

What is Hoshin Kanri? Hoshin Kanri is a management process that aims at aligning a company’s functions and activities with its strategic objectives. The process involves developing specific plans which consists of precise goals, actions, timelines, responsibilities and metrics. Hoshin Kanri usually starts with a high level organizational plan that involves setting of all the necessary goals required to achieve ... Read More

Read MoreVenetian Arsenal- Venice Ship Building Using Mass Production

venetian war scene | Source The Venetian Arsenal venetian arsenal,venice,italy: Venetian Arsenal, Campo de L’Arsenale, 30122 Castello, Venezia, Venice, Italy get directions Venetian Shipyard | Source In summary Venice was a powerful economic and military city-state To maintain dominance and protect her interests, she had to be well equipped militarily Used mass production methods in the manufacture of ships and arms The arsenal employed ... Read More

Read MoreHIPAA FINES: 10 Common HIPAA Violations to Avoid

The US DHHS enforces the HIPAA Regualtions | Source Mistakes happen and it is normal for human beings to make errors. But when it comes to HIPAA regulations, making mistakes can cost you and your company millions of dollars in fines or settlement payments. Many mistakes have been made in the handling of personal health information and some have just been plain ... Read More

Read More60 Common Examples of Poka Yoke

What is Poka Yoke? Poka yoke, ‘mistake-proofing’ in Japanese, prevents avoidable mistakes from occurring. This applies to any environment, be it in manufacturing, hospitals or even in the home. This article looks at the following: Meaning Origin and application Examples in the automotive industry Error-proofing examples in manufacturing Mistake-proofing examples in daily life Other examples Definition of Poka Yoke ... Read More

Read MoreJishu Hozen: Autonomous Maintenance Pillar of TPM

Total Productive Maintenance Total Productive Maintenance is a holistic approach for increasing productivity by ensuring availability of the machine used in the production of goods. It empowers employees to take control of the reliability of machines by doing basic maintenance tasks like oiling, lubrication and tightening. Jishu Hozen Definition & Meaning Jishu Hozen is a Japanese word that means autonomous ... Read More

Read MoreTPM Pillars—Eight Pillars of Total Productive Maintenance

What is Total Productive Maintenance (TPM)? Total productive maintenance is a complete system for maintenance of equipment that aims at achieving an optimal production environment devoid of defects, downtime, stoppages and accidents. One distinct advantage of total productive maintenance is that it empowers the shop floor to work in a concerted manner to ensure that machines are functioning at their ... Read More

Read MoreLean Kata: Daily Improvement Practice Routine

After unsuccessfully trying to implement lean, most managers end up blaming the workers as being against lean. While resistance is to be expected in any change program, the reasons for lean implementation failure are many. But the most ignored aspect when trying to implement lean is the psychology of change within the organisation. Everybody behaves in a certain way because ... Read More

Read MoreThe Lean Transformation of Tesla and Elon Musk

Tesla aims at mass producing electric cars and make them as ubiquitous as gasoline powered cars. To do that, they have to produce affordable cars and meet the huge demand the promise of pollution-free transportation is generating in the market. The launch of the mass market Tesla Model 3 has been dogged by production problems with the number of unfulfilled ... Read More

Read MoreHow 3D Printing Can Improve Factory Productivity

The main objective of lean manufacturing is to reduce the time it takes from when a customer places his order to the time the order is delivered. By removing wasteful activities along the value chain, there is a significant reduction in lead times and — ultimately — costs. 3D printing is proving to be a useful tool in eliminating some ... Read More

Read MoreHitachi Reopens Factory after Major Refurbishment

Hitachi opened its excavator factory in the Netherlands after 6 months of major renovations. The factory now has the capacity to produce 7000 units, up from the previous 5000. This revamp was necessitated by increasing demand for the company’s high quality products. Speaking at the opening ceremony, the factory’s General Manager Marco Verhoef said, “We are ready for the future, ... Read More

Read MoreOEE: Calculation of Manufacturing Performance Ratio

OEE is a metric that is used for understanding the ratio of actual productive time to planned production time. Because of the low OEE in most manufacturing plants, there is a huge opportunity for improvement. WHAT IS OEE? Overall Equipment Effectiveness (OEE) metric answers the question – what percentage of the planned production was actually achieved? The ideal OEE of ... Read More

Read MoreBeer Game: How the Bullwhip Effect in Supply Chains Happens

Exploring the Bullwhip Effect using the Beer Game | Source What Is the Bullwhip Effect? The bullwhip effect in supply chains is the increase in order fluctuations as one moves upstream. It starts with a small signal in the consumption of goods by a downstream step. This small signal is misinterpreted ... Read More

Read More5s at Home: Use this Lean Manufacturing Tool to Declutter

Clutter overflow by Puikkibeach on flickr (cc by 2.0) | Source The amount of disorganization in your house has now become a major problem, and you are wondering what to do with all the piles of materials that are building up in every available space. You decide to do something about it but do not know where to start, and it ... Read More

Read More14 Lean Management Principles

A lean organization achieves its goals through the application of time-tested techniques and tools, backed by a firm philosophical foundation of continuous improvement and learning. Behind the lean paradigm are a set of management principles that when consistently applied, result in business success regardless of one’s industry. What is Lean Management? Traditionally, we expect management to be the function that ... Read More

Read MoreWhat is Heijunka?

By definition, heijunka is a production leveling and scheduling tool that is used in lean manufacturing to utilize the available capacity within an organization effectively. Responding flexibly to customer demand increases profitability. The reality necessitates production leveling and scheduling in the business world where customer demand tends to fluctuate on a day to day basis but when looked at from ... Read More

Read MoreHow Poka Yoke Improves Safety

Thousands of workers die or get injured on the job in the US each year. Workplace injuries and fatalities are financially and socially [PDF] costly. Safety features are at the forefront of most product design. No one wants to be the reason a customer was hurt or killed because of poor quality or a dangerous feature went unnoticed. Rigorous testing ... Read More

Read MoreHeijunka — Production Levelling in Manufacturing

Manufacturing products is not for the faint hearted. The coordination of resources required to convert raw material to the final product can be exhausting on a normal day. To add to this, customer orders may fluctuate from day to day — leaving the plant guessing on what and how much to produce. Wouldn’t it be nice if customer orders were ... Read More

Read More10 Ways to Improve Your Office Productivity

A hurried office can be both unproductive and unsafe. If you are too distracted and can’t focus on the content of your work, chances are you are likely to make a good number of critical mistakes. Here are a few tips and tricks you can use to increase your productivity and at the same time make your job easier and ... Read More

Read More10 Reasons Why Organizational Change Programs Fail

Change management can sound like a scary endeavor and can cause its own crisis if not implemented properly. Sometimes change is necessary but done properly with the right tools and intentions, can enhance your business and product to be the best it can be. By steering clear of the ten mistakes below, you can give your program an excellent chance ... Read More

Read More10 Mistakes Companies Implementing Lean Manufacturing Make

Toyota’s vaunted production system has been around for over 50 years. During that time, they have improved on their quality and productivity — in the process capturing a significant portion of the world auto market. This success has led other companies to try and implement lean manufacturing — in most cases with limited success. Why is this? The short answer ... Read More

Read MoreExamples of Poka Yoke in Daily Life Situations

What is Poka Yoke? Poka Yoke is a method for drawing attention to — or preventing the occurrence of — defects. These include quality or safety defects in processes whose output is physical products and services. By addressing off-spec conditions early on in a process, costly defects in the final product are significantly reduced. Poka Yoke also refers to features ... Read More

Read MoreTesla Mega-Battery Goes Online in Australia

The world’s biggest Lithium-Ion battery began dispatching power into Australia’s grid on Friday. It delivers an audacious promise by Tesla’s Elon Musk to build the battery in 100 days or provide it for free. Tesla’s Powerpack battery is connected to a wind farm in South Australia. It has the capacity to supply 30,000 homes for one hour, which is three ... Read More

Read More