Lean Opinion

We, in Lean Factories, finds it valuable to express our opinions and our own insights on matters that touch on Lean Manufacturing.

Below are some of our inputs that we would like to share and we hope that we can get your opinions too. When it comes to Lean, your opinions matter.

JIT Implementation: Key Challenges and Solutions for Success

Just-in-time (JIT) methodology focuses on producing and delivering products precisely when needed, without waste or delay. JIT has become increasingly popular in supply chain management due to its ability to reduce costs, improve efficiency, and increase customer satisfaction. However, implementing JIT does not come without its own set of challenges. This article will explore the key challenges of JIT implementation ... Read More

Read MoreLean Project Management Tools: What You Need to Know

A project manager's life is a constant juggling act. You have to ensure that all your tasks are on time and within budget, while also keeping the team motivated and happy. The last thing you need is more work! Fortunately, there are plenty of tools out there to help you manage your projects more efficiently, but which ones should you ... Read More

Read MoreTop Reasons Why Lean Is Not Only For Manufacturers

When people think of Lean, their minds often wander to manufacturing. While Lean was originally developed to benefit the manufacturing industry, the fact that it has been practiced effectively has raised the eyebrows of many other industries. These industries now seek to employ the effective practices of lean and recreate the same success that it has created in manufacturing. Let’s ... Read More

Read MoreHow to Know if Your Facility is Truly Lean

Now apart from approaching and ensuring success, the Lean methodology has a slew of other benefits as well. For starters, the wasteful actions that Lean takes care of will allow for a more focused workforce. This isn’t just a focus on their tasks, but on things that contribute great benefit to a facility’s success.

Read MoreTop Benefits That Lean Manufacturing Can Provide Businesses

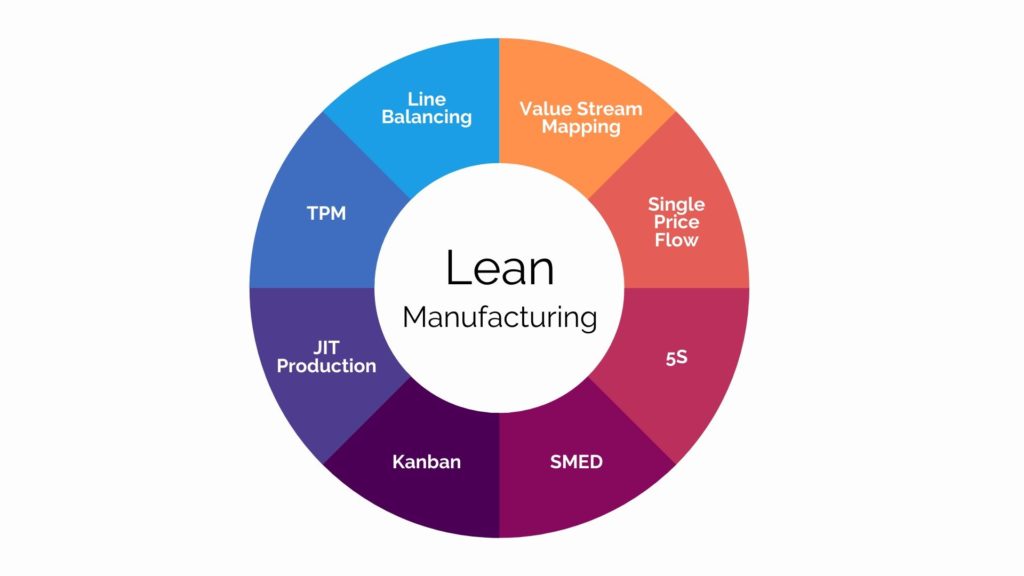

Efficiency will always be a big benefit to each and every business. The act of producing more with less will save on time, efforts, and resources, while also increasing the profit and success of a company. That is why Lean Principles is particularly useful, especially to the manufacturing industry.

Read MoreHow to Apply Lean Manufacturing Principles to Engineering

Studies have shown that 80% of a product’s cost is determined when the design of the product is being engineered. The factors that contribute to the product’s cost at this phase include:

Read MoreEstablishing Lean Factory That Works: Top Tips to Consider

Lean is a philosophy and system that can be applied to a variety of workplaces or processes. The main goal of lean is to do away with any waste wherever they can be found within your business. Fortunately, the lean system and all of their benefits can be applied to factories. The question now is, how does a business establish a lean factory that works? Let’s go over several top tips that businesses consider when applying lean to factories.

Read MoreHow Can Lean Logistics Benefit Your Business

People think that terms like, “Lean”, “Lean Manufacturing”, and “Lean Logistics” all mean the same thing. While they pull from the same philosophy from Japan years ago, there are some differences to them. When people just say Lean, it refers to a general plan of attack that can be applied to any process or any business with the goal of eliminating waste. When the term “Logistics” is added, it adds a whole new complexity to how the Lean methodology is used. It then focuses the Lean principles to a different more complex set of operations.

Read MoreLean Manufacturing Training Materials

Using Lean principles in manufacturing is a great way to improve the quality of a product and service. Moreover, if used correctly, it will definitely improve a company’s financial performance overall. If you are in the manufacturing industry, manage a manufacturing industry, teach employees ...

Read MoreShingo Guiding Principles

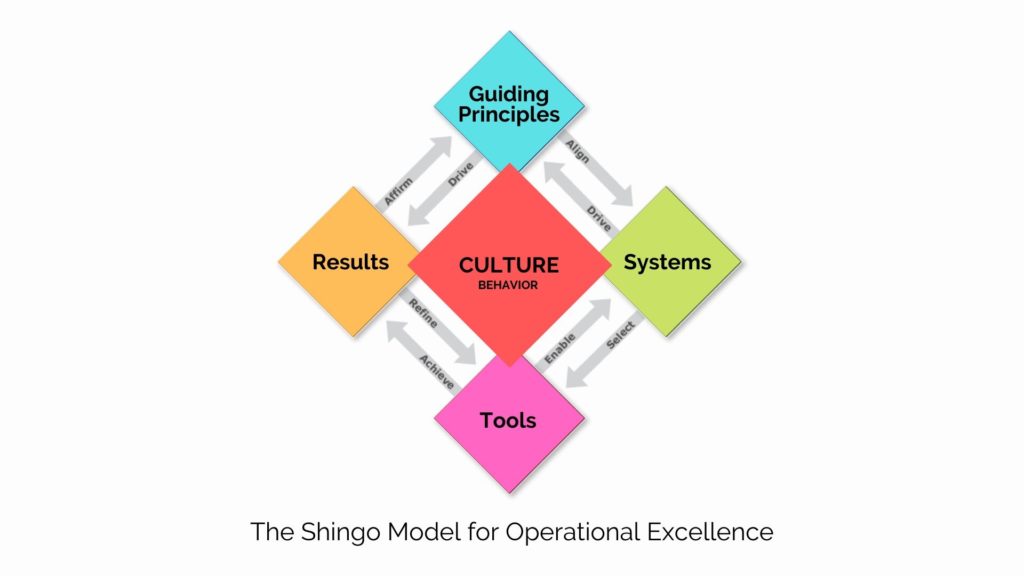

For people who are handling businesses and processes, there is a misplaced focus on tools. The belief is that the right tool will solve most, if not all problems. However, another belief states that the tools are not the endgame. They aren’t even the starting point. Enter the Shingo Guiding ...

Read More3 Reasons Why Jidoka is not an Important Lean Tool Anymore

Jidoka Basically, Jidoka is a Japanese word that means giving machines human intelligence — this helps in building in quality into products. Stopping to fix problems is and developing countermeasures ultimately leads to better productivity in the long run. But Jidoka is not only about machines that can stop themselves. In line with the TPS philosophy, Jidoka is also about ... Read More

Read MoreKaizen Musings — Defective Provision Processes

Companies fail at lean provision because they still use mass production methods. Satisfying customer demand may look easy -- especially with today's technological advancements. The truth is that providing what the customer wants is not easy. This is because the whole process is ...

Read MoreLean Healthcare : Implementing a Hospital Lean Management System

Lean is slowly catching on in healthcare because of the immense benefits that could be gained in quality, cost and delivery.

Read MoreKaizen Musings — Why Is There So Much Stress At Work

Why is there so much stress at work? Work related stress can be overcome through simple habits.

Read MoreBenefits of Total Productive Maintenance

Benefits of Implementing Total Productive Maintenance Why do we practice Total Productive Maintenance? The simple answer is that we want our critical machines to be in a good working condition at all times. When this happens, we are able to satisfy customer demand. Total Productive Maintenance improves flow within the value chain through elimination of downtime caused by machine breakdowns. ... Read More

Read MoreThe Lean Transformation of Tesla and Elon Musk

Tesla aims at mass producing electric cars and make them as ubiquitous as gasoline powered cars. To do that, they have to produce affordable cars and meet the huge demand the promise of pollution-free transportation is generating in the market. The launch of the mass market Tesla Model 3 has been dogged by production problems with the number of unfulfilled ... Read More

Read More