OEE is a metric that is used for understanding the ratio of actual productive time to planned production time. Because of the low OEE in most manufacturing plants, there is a huge opportunity for improvement.

WHAT IS OEE?

Overall Equipment Effectiveness (OEE) metric answers the question – what percentage of the planned production was actually achieved? The ideal OEE of 100% indicates that good quality products were manufactured with no downtime and within the planned production time.

Companies can use current OEE as an important reference point for future improvement activities. An OEE score, in this case, serves as a baseline — a starting point from which further improvement can be made.

OEE is also a good measure of how well an organization is doing vis-a-vis other players in the same industry.

At 100% OEE performance, a company is in an ideal state — every product is produced with zero downtime, best quality and with no overtime. This rate of performance shows the high-level goal to be aimed at. It may be almost impossible to achieve but it is the ideal to strive for.

Companies that have matured in their implementation of lean manufacturing and have stayed on the journey can achieve an OEE rate of 85%. This score is considered a world class performance and few companies can dream of achieving it.

A majority of organizations have an OEE score of below 60%. This means that the scope for improvement is very large.

OEE CALCULATION

There are a number of ways in which OEE is calculated.

One straightforward OEE calculation is to determine the percentage of good parts actually produced to the percentage that could be produced at the specified cycle time.

The OEE formula is:

(Total Parts Produced to Specification x Ideal Cycle Time) / Planned Production Time

The Total Parts Produced to Specification is the output that is of defined quality

Ideal Cycle Time is the designed rate of output a machine or process is capable of achieving under current circumstances

Planned Production Time is the scheduled period for production

CALCULATING OEE USING AVAILABILITY, PERFORMANCE & QUALITY

While the above formula is easy to understand and use, it still falls short of giving a full understanding of the thing behind Overall Equipment Effectiveness as a useful production metric.

To get an expanded understanding of OEE Calculation, we look at three metrics:

Availability

Performance

Quality

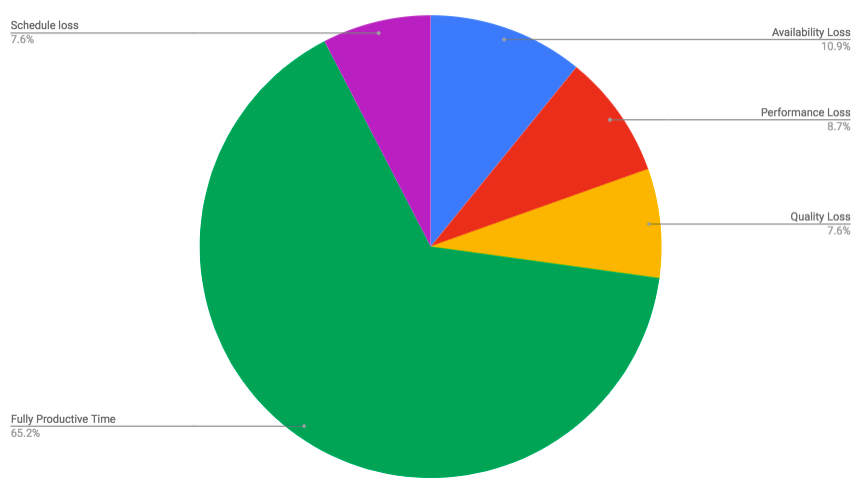

The fully productive time is what remains after availability, performance and quality losses are removed.

Availability Loss in OEE Calculation

This part of the OEE calculation considers any aspect that may stop production between runs. Factors that can impede production include material stock-outs, machine breakdowns, and change-overs.

To calculate availability, we ask ourselves this question — what percentage of the planned production time was used to actually produce? Availability, therefore, is simply a ratio of the time used in actual production to the time planned for production. To get the actual time that was available for production, we deduct any stoppages from the planned production time.

The formula:

A = APT/PPT (Actual Production Time / Planned Production Time)

APT = PPT – ST (Stoppage Time)

Availability is just one of the components of OEE calculation — all three have must have a high score for the overall OEE score to be high.

Performance Loss in OEE Calculation

The Performance Loss metric within the OEE calculation answers this question — given the installed capacity, what was the output? Performance Loss is calculated by taking into account the known Cycle Time per piece and multiplying it with the total number of pieces actually produced.

You then juxtapose that figure with the pieces that would have actually been produced. In short, use this formula:

Performance Loss = Total Number of Pieces Actually Produced / Number of Possible Pieces

If the total number of parts produced equals the total possible (given the cycle time) a number of parts, then there is no performance loss to report.

However, we must remember that all the three metrics of Availability, Performance, and Quality must be high for the Overall Equipment Effectiveness to be world class.

Quality Loss in OEE Calculation

Quality means producing something according to the customer’s specification. Quality loss is a ratio of the number of good parts actually produced within a production cycle to the possible number of parts.

If all the parts that come off the line are of good quality, then there is no loss. The Quality Score, in this case, will be 100%.

Quality score calculation:

Quality = Number of Good Parts / Total Number of Parts Produced

All parts that did not meet specifications, even those that were later on reworked, should be considered as poor quality.

OEE KPIs

At the managerial level, OEE calculation is a good way to get a clear picture of how well the plant is performing. However, using OEE for shop floor KPIs on a day to day basis can be overwhelming to the staff.

It is better to give shop floor staff targets based on aspects of the OEE score such as quality. If workers spend their day improving aspects of production within their scope, the OEE will naturally improve.

Using lean manufacturing tools such as Total Productive Maintenance (TPM) can help increase uptime of equipment as well as the rate of production. These tools can also be used to improve the quality of the products coming off the line.