What is Poka Yoke?

Poka yoke, ‘mistake-proofing’ in Japanese, prevents avoidable mistakes from occurring. This applies to any environment, be it in manufacturing, hospitals or even in the home.

This article looks at the following:

- Meaning

- Origin and application

- Examples in the automotive industry

- Error-proofing examples in manufacturing

- Mistake-proofing examples in daily life

- Other examples

Definition of Poka Yoke

This is a Japanese word that means mistake proofing of equipment or processes to make them safe and reliable.

These are simple, yet effective design features that make it almost impossible for errors to occur.

In fact, the original term was Baka-Yoke or “fool-proof”. Due to the inappropriateness of the term, “mistake-proofing” became the preferred term.

The aim of mistake-proofing is to remove the need for people to think about the products or processes they are using. This is because the products have a design that makes it impossible to use them in the wrong way.

When someone uses the product the wrong way, it does not function and it becomes obvious to the user that they are doing the wrong thing. The simple yet effective design features make it difficult for errors to occur during usage of the product.

Origin and Application

The concept developed out of the need to achieve quality in production processes. It was Shigeo Shingo, one of the pioneers of the Toyota Production System, who proposed the concept. He was a quality guru who proposed the idea of ‘Zero Defects’ as a quality paradigm.

The thinking was that a process should be able to detect and prevent errors from occurring. This would lead to a final product of high quality.

Poka Yoke Examples in the Automotive Industry

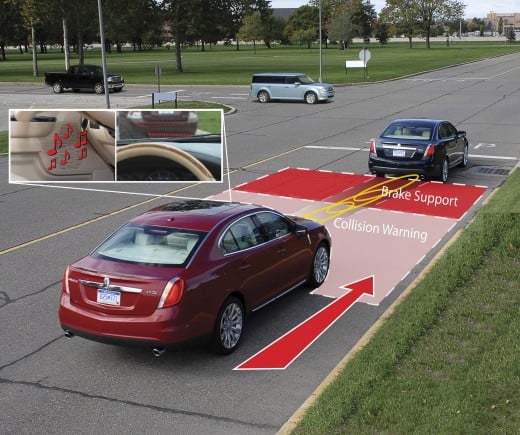

This form of mistake-proofing helps prevent accidents | Source

Many people lose their lives or get maimed through vehicular accidents each year. Safety of users of automobiles is of paramount importance and many measures have been taken to make them safe. The following are examples of mistake-proofing in the automotive industry:

-

Radar and video cameras in new vehicle models are able to tell the distance and speed of other road users. This helps them prevent collisions in case of sudden stops. The device here is more of a warning and preventive measure but it does not strictly fit into the concept of behaviour modification. The driver may choose to ignore the warning which will lead to an accident. The device does not stop the accident from happening in the first place.

-

Automatic breaking system stops the vehicle in case the driver fails to brake when an obstacle suddenly appears on the road. If the system above is used with this device, it will be a better preventive measure as the system will note that a warning has been ignored. The sensors will then kick in and stop the vehicle – a key component of poka yoke is at play here.

-

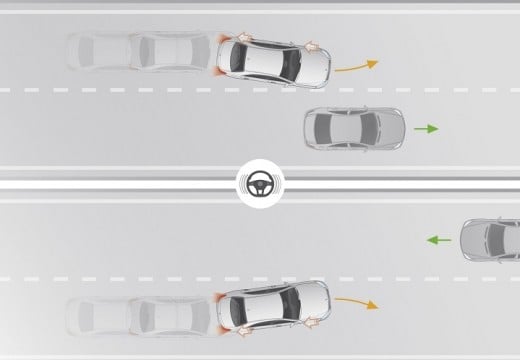

Lane-keeping assist alerts the driver that he is about to deviate from his lane. If the driver is not responsive, the vehicle intervenes and returns to the correct lane on its own. This device also fits well with the automatic intervention philosophy of poka yoke. There is no way the driver will commit an error because the vehicle will stop him from doing so.

Lane assist is a form of mistake-proofing that prevents accidents

- Electronic stability control helps reduce the possibility of accidents that can occur when a vehicle skids uncontrollably due to over-steering by the driver. The condition being controlled here is the slippery road — when this condition comes into play the system kicks in to prevent an unwanted result from occurring.

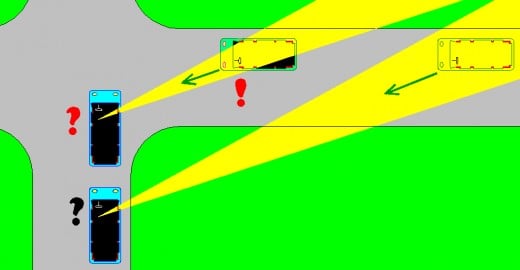

- Cross-traffic alerts warn drivers of impending traffic when they are reversing from a parking position. Like the first example of mistake-proofing in the automotive sector, this device is more of a warning and must be used in-conjunction with other devices to be successful.

- Adaptive headlights are able to respond to the conditions on the road so as to assist the driver have better visibility. For example, they are able to illuminate curved roads and also during bad weather.

- Airbags deflate quickly after an accident to prevent injury to the occupants of the vehicle.

- Seat belt pre-tensioners assist in holding the passenger in place in case of an accident and prevent them from sliding through.

Seat belt pre-tensioners prevent occupant from sliding under during accidents, a form of pokayoke| Source

- Blind spot assist warns the driver when there are objects within the blind-spot range that are not visible.

Blind spot assist is a form of Poka Yoke | Source

- EBS braking distributes power evenly and the discs expand symmetrically when hot. This minimises uneven tear of the discs

- Brakes that continuously self-monitors and reports any problems to the central control unit. This prevent the likelihood of an accident attributable to the breaking system

Poka-yoke in these plugs ensure they can only enter in a certain way

Poka Yoke Examples in Everyday Life

Products that we use every day have features that make them safe and convenient. The following are a few examples of how mistake-proofing is used for everyday household products:

- Micro-wave oven does not work until the door is shut.

- Washing machines only start when the door is closed and cannot be opened until the cycle is over**.**

USB cable can only enter facing one side | Source

This electric socket has used pokeyoke in a cover to make it child-proof | Source

-

Electric plugs have an earth pin that is longer than the other pins and is the first to make contact with the socket. The protective shield of the neutral and earth sockets are then opened safely.

-

Electric sockets are shaped in a manner that only one way of plugging-in is possible. This prevents the possibility of a short-circuit occurring.

-

Child resistant tops for medicines and household chemicals makes it difficult for children to consume the contents.

-

Elevator doors have a sensor that causes them to open when there is an obstruction-this prevents injury to someone trying to enter as the doors are closing.

-

Box cutters have a retractable blade that only pops out when the handle is held.

-

Lawn mowers have a safety bar on the handle that when released, switches off the machine.

-

Circuit breakers in the home electrical system prevent electrical overloads.

-

Overflow outlets in bathroom and kitchen sinks prevent flooding of the house when the drain is blocked.

-

The Door of a washing machine or dryer makes the machine stop when it is opened, so as to prevent injury from accidents

Examples of Poka Yoke in Manufacturing

In lean manufacturing systems, poka yoke also includes a philosophy of constantly working to prevent mistakes from occurring in the first place. The internal processes in lean manufacturing systems are supposed to produce quality products the first time. Error-proofing in this case is a quality assurance technique that ensures quality is in-built and results in better products.

For the final product to be of high quality, all the inter-connected process steps have to give first time quality. If an mistake or defect is allowed to move to the next step, the likelihood of it appearing in the finished product is very high. It is therefore necessary to develop ways of preventing a defective product moving to downstream process.

This is important because a finished product is considered to be the most expensive form of inventory due to the accumulated costs along the value chain. If a defect occurs in the finished product, the costs of production increase due to the effort required to correct it.

- Magnets in a grain packaging plant detect and remove metal pieces before they are packed.

- Interlock switches which detect the position of a machine guard and switch off the machine when the guard is lifted. The machine will never operate when the guard has been lifted and this prevents accidents to the operator.

- Light curtains in a factory detect when someone is near very dangerous machines and switches off the machine to prevent injuries.

- Safety mats near machine areas that pose a danger automatically trigger stoppage when someone steps on them. This prevents injury to personnel (such are technicians) who are trying to access dangerous sections of a machine.

- Power guards on high inertia machines with moving parts prevent opening until the parts have stopped completely in order to prevent accidents.

- Machines that must be controlled using both hands ensure that some distance is kept between the operator and dangerous machine parts.

- In the food industry, gloves and other small pieces of personal protective equipment must be blue in colour for ease of detection in case they fall into food. This is because blue foods are rare in nature and the color difference makes it easy to detect that a foreign object has fallen into the food.

- Using standardized containers at the workstation enables workers to know exact quantities without having to weigh or count the contents.

- Use of colour coded date labels to mark the production dates of products. This way the different batches are easily identifiable for the purpose of product rotation. The system is especially useful in the food industry where rotation of batches is very important because of hygiene considerations.

Mistake-Proofing of Products

Safety concerns necessitate the use of mistake proofing techniques on the final product in order to prevent harm to the final consumer.

It also provides ease of use to the product so as to enable the final consumers to be able to solve their problems effectively.

Adding user-friendly features to a product aims at solving safety as well as convenience concerns and makes it almost impossible to use the product in the wrong way.

Other Poka Yoke Examples

There are many other examples of products that have fool-proofing ranging from USB cables to child proof sockets. Here are a few examples:

- Glow-in-the-dark strips around the toilet bowl prevent users from urinating on the sides.

- Mop slippers save time for the busy person as they prepare to go to work or school.

- Scrap collecting bowl has a ledge that is attached to the table top to collect vegetable scraps before they fall on the ground.

- Oven rack guard prevents accidental burns as one is removing food from the oven chamber.

- Locator stickers that are put on commonly lost items such as keys and can be traced using the phone.

- Upside-down tomato sauce bottles enable the consumer to use up all the tomato sauce and also lets the water that collects at the bottom come out first.

- Mobile phones are designed in such a way that when they fall, the cover separates so as to minimise the shock that would damage them.

- Color-coding of electrical wires is meant to prevent short circuiting that can occur if they are not matched properly.

- Ice blocks that prevent someone from drinking too much.

- A company invented a fork that tells you when you have eaten too much thus preventing you from getting over-weight

Poka Yoke Examples in Nature

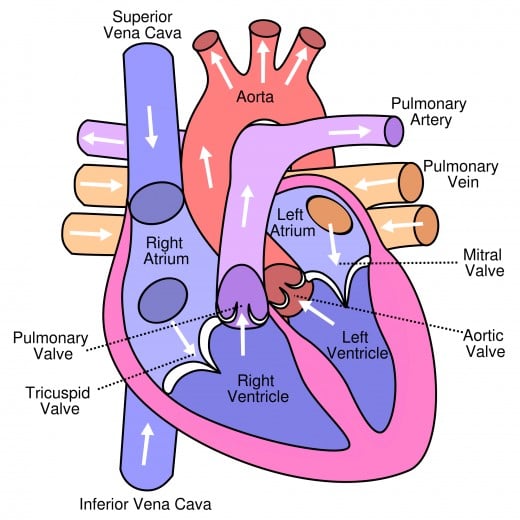

Valves are an error-proofing example in nature that prevent back-flow of blood

Mistake-proofing also occurs in natural systems and the human body system is a good example of how it works to prevent errors from occurring:

- Coughing is a natural reaction that prevents the error of foreign bodies from entering into the lungs. The sensitive wall linings of the respiratory tract detect and eject minute particles through coughing.

- Veins have valves that are designed to prevent the error of back-flow of blood as it travels through the system. They also allow some blood to collect within the system without busting as they have a larger internal diameter.

- Arteries have thick walls that can withstand the high pressure that blood from the heart exerts on the circulatory system.

- Tearing is a necessary reaction to the entry of foreign bodies into the eye.

- Mucus membrane traps bacteria and prevents the error of pathogens entering the system.

- The skin is the first defence against entry of foreign bodies and the oils and enzymes prevent harmful bacteria into the human body.

- Inflammation reaction of swelling happens when blood vessels leak fluid into the tissues. The chemicals attract white blood cells (phagocytes) that eat germs and dead/ damaged cells. This reaction prevents the spread of harmful toxins and pathogens to the rest of the human body and is a form of natural error-proofing.

Error-Proofing in the Space Industry

The space industry requires accurate procedures to be constantly carried out so as to ensure the successful completion of space missions. Any small error in the implementation of these procedures can lead to a major disaster.

The industry has therefore developed many mistake-proofing devices to prevent errors from occurring and this has resulted in the high success rates of space mission over the years. The following are a few examples of error-proofing in the space industry:

- Escape capsule is designed to help the astronauts safely return to earth in case if there is an emergency during launch of the spacecraft. An abort motor fires over half a million pounds of thrust to steer the capsule away from the booster rocket. Another motor steers the capsule in the right direction and then a jettison motor separates the escape rocket from the capsule which has parachutes to allow it to safely land on earth. This error proofing device will save lives in case the launch of the rocket fails.

- Checklists used in the pre-flight preparation are detailed and are designed to ensure all the parameters are within the allowed range before the flight can commence.

Fool-Proofing in Nuclear Power Plants

Nuclear accidents can have devastating effects as was seen in the Chernobyl disaster. Nuclear power plants use the defense-in-depth concept of barriers to the prevent fission material from being released from the reactor core to the environment.

The fuel rods have cladding that prevent the release of fission material in the event of a melt-down. The reactor is designed to assist in the cooling of the rods in case there is a decrease in the cooling water in the core. This is very important as the heat released during the decay of radioactive material can start a chain reaction that is unstoppable.

Error Prevention in the Service Industry

The service industry is very important in that there is direct and constant interaction with the customer and any failure on the part of providers of services can result in losing good business.

This failure to serve a customer as per their expectation can be considered an error and many service providers have put in place a number of error-proofing processes to prevent this from happening.

The following are just a few examples of how service providers mitigate against the chances of causing mistakes in their businesses:

- Electronic tags in airline luggage handling systems ensure that passenger luggage is not lost after check-in. Airline staff are able to locate misplaced luggage anywhere in the world as the tag contains all the necessary passenger and flight information that is used in tracking it.

- Electronic waiter pads in restaurants ensure that the right order goes to the right table at the shortest possible time. This order matching technology prevents the error of waiters taking the wrong order and also enhances fast delivery to the customer.

- Queue management systems in banks and other public venues are designed in such a way that customers are served according to the order in which they came in promptly thus preventing customer dissatisfaction.

Examples in Aeroplanes

The fact that air travel is considered to be safer than road travel can be attributed to a number of fool-proofing devices that have been put in place over the years. While air accidents still occur, they have significantly been reduced because of these devices:

- De-icing chemicals make it difficult for ice to form on the wings of aeroplanes which can cause serious accidents.

- Auto-pilot keeps the plane flying in case of inclement weather or when the pilot is ill-disposed.

- Captain meals on planes must be different from the meals served to other passengers so as to prevent cases of food poisoning affecting the pilot, which can be very dangerous especially mid-flight.

- Fuel jettisoning is an important procedure during emergency landings as it prevents major fires from the fuel held in the tanks.

- Instrument control-panel is located in such a manner that the pilot and engineer are able to view all readings easily.

Error-Proofing of Medical Devices

Roller coasters have error-proofing devices for safety

Conclusion

From the above comprehensive list of examples, it becomes obvious that there are certain characteristics of error-proofing devices that help in achieving the aims of mistake-proofing. These characteristics include:

- Simplicity, which means that the solutions are not complex and unambiguously resolve the problem of error occurring.

- Automatic Nature: they do not require any further intervention from the person using the device.

- Safety is a key characteristic of poka yoke devices in that they also prevent the users from injuries.

- Feedback is immediate in the case of failure when the conditions go out of specification.

- Quality is ingrained in the process and the solutions encourage the right methods to be used by operators of the devices. It is a way of standardizing the correct methods of performing a process.

- Location at the source of a potential problem within a process.

- Reduction in the number of process steps required to complete a process as the inspection aspect is minimized or completely eliminated.

Need Help Implementing Poka-Yoke?

Use our free interactive tool to find the perfect mistake-proofing solution for your specific problem.

Launch Poka-Yoke Finder Wizard